Expanded Metal Machine for Expanding, Pressing, Flattening, Shearing, Cutting / Slitting

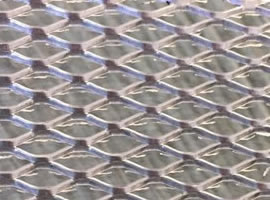

PuRuiSe manufactures and exports Production Line and Machines for producing of Expanded Metal of various materials and types. Mainly three steps involved in Expanded Metal Processing: Expanding, Flattening and Shearing. Expanded Metal is manufactured by expanding press from basic metal plates. Simultaneously slit and cold-formed, the steel or other metal sheets expands the slits into diamond shaped openings of uniform size and regularity. By expanding a metal plate in a press, the metal stretches, leaving diamond-shaped voids surrounded by interlinked bars of the metal. The most common method of manufacture is to simultaneously slit and stretch the material with one motion. Then the metal mesh sheets are flattened with a flattening machine, then cut by a shearing / slitting machine into sheet of sizes.

Automatic Expanded Metal Press

PuRuiSe expanded metal press is designed to process carbon steel, galvanized steel, stainless steel, aluminum, and a variety of coppers. With automatic control and auto feeding system, our machines have been exported to over 30 countries and regions: Thailand, U.A.E, Indonesia, Italy, Ukraine, Turkey, Australia, Mexico and etc.

CNC Plate Shearing Machine

Automatic CNC cutting machine for shearing (cutting) of color steel plate, stainless steel plate, GI metal plate, welded wire mesh, chemical fiber felt, rubber division strip, expanded metal mesh, cold rolling steel plate.

This machine has electric operation, automatic feeding, saving time and labor with following advantages:

Auto Feeding, feeding distance and speed can be adjusted;

Leveller be available;

Splitting to strips available;

Cutting, level, Splitting, Bending options at choice;

Touch screen operation, easy and clear.

Metal Mesh Flatten Machine

Expanded metal mesh flatten machine is special designed for expanded metal flattening. It’sa necessary equipment for expanded metal production. It can make expanded wire mesh smoothly.

Flattening machine in different width and different designs are supplied. We supply four-roller flatten machine, two-roller flatten machine, manual flatten machine, hydraulic flatten machine, etc. Currently the machine isapplied to processing expanded metal with a maximum sheet thickness of 5mm and width between 0.5m to 2.5m.

Machine Models for Setting Up Manufacturing Factories in Ukraine, Turkey, Syria, Australia, Brazil, UAE, Iran, India

Aluminum Expanded Mesh Machine for Ukraine

Suitable for aluminum meshes production

AMM-U18 Model Aluminum mesh machine is designed to produce aluminum expanded meshes from rolled (coiled) aluminum strips. This mesh machine is supplied with punching tools.

Technical Data

The aluminum expanded meshes are made in two patterns:

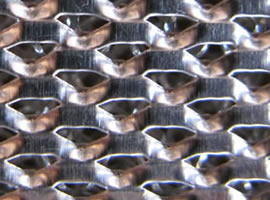

Fish-scale aluminum mesh

Aluminum Expanded Mesh, Fish Pattern, Size 1.3 x 3.4 x 3.8 x 5.8mm

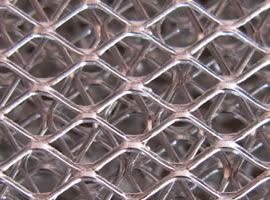

Diamond scale aluminum mesh

Aluminium diamond mesh, size 2.8x4.6x3.8x5.8mm

Material to work with the mesh machine:

The aluminum strip width – max. 500mm or 600mm

The mesh parameters for both expanded mesh types:

Fish-scale aluminum mesh (Strand thickness – 0,3+0,1mm, Strand width -2,0mm):

- SWO – 1,3 - 1,4mm,

- LWO – 3,4 - 3,5mm,

- SWD – 3,8 – 4,0mm,

- LWD – 5,8 - 6,0mm.

Diamond scale aluminum mesh (Strand thickness – 0,3mm+0,1, Strand width -0,8mm):

- SWO – 2,8 - 3,0mm,

- LWO – 4,6 - 4,8mm,

- SWD – 3,8 – 4,0mm,

- LWD – 5,8 - 6,0mm.

We supply samples of fish-scale and diamond-scale meshes to be made using the mesh machine.

Galvanized Metal Mesh Machine Export to Syria

Designed for production galvanized expanded metal mesh

GEM-S36 Model Expanded Metal Machine for galvanized expanded metal mesh in diamond pattern: 3x6mm

Technical Data:

Mesh hole size : 3x6 mm

Metal sheet width: 1000mm, 1200 mm

Sheet length: 6 m

Galvanized steel sheet thickness: 0.3 mm to 0.4mm

Diamond mesh panels to be made with the machine

Expanded Sheet Flattening Machine to Turkey

Designed to flatten expanded metal mesh

Technical Data:

Working material width: 1500mm

Working material thickness: 0.5 to 3mm

Roller diameter: 400 to 500mm

Motor power: 7.5kw

Machine weight: 6.5MT or 5.5 MT

Filter Mesh Expanding Machine Export to Brazil

Designed for filter industries

The Press

Technical data:

Sheet metal width: 800mm

Material thickness: 0.65mm

Supplied with Flattening Machine

for expanded metal (steel) machine

Flattening sheet width: 1000mm maximum

Material thickness: 0.65mm

Expanded Diamond Mesh Machine Export to India

Designed to produce 100 mm x 200 mm diamond mesh

Technical data:

Material thickness to process: Max 3 mm

Expanded metal size to be produced with the machine:

SWM (Short way mesh) 100 mm, LWM (Long way Mesh) 200 mm

Sheet Width Maximum 2.5 m

Stainless Steel Expanded Metal Machine to Uganda

Designed to flatten stainless steel expanded metal

Expanded metal machine 1250x0.9mm to 1250x2.5mm with uncoiler, 12 tons max weight

Expanded Metal Press Export to Australia

Designed with 2 Mt decoiler

Expanded metal press supplied with extra set of blades

Designed with a 2 ton decoiler

Aluminum Expanded Metal Machine Export to Turkey

Designed for production of aluminum filter applied for HVAC industry

Flattening machine for production of aluminum filter

Technical data:

Aluminum sheet thickness: 0.35 mm to 0.4 mm

Mesh size: length 7 mm by 4 mm width, length 3 mm by 1.8 mm width

Filter rolls width: 1 meter.

Max Production speed: 40 meters per 8 hr shift

Min Production speed: 15 meters per 8 hr shift

Expanded Mesh Angle Bead Machine for UAE

Designed for production of angle bead and plaster mesh stop

Machine for production of Galvanized Iron and Stainless Steel Angle Bead, a kind of light expanded mesh sheet product.

The machine can be used for production of angle bead and plaster stop by changing of expanded dies.

Technical data:

Supplied with one set expanded dies for angle bead ( 10sw x 25 lw) ; expanded dies for drywall plaster stop ( 10 sw x 25 lw )

Material Thickness: 0.30mm to 0.70mm

Material Grade : Galvanized Steel and Stainless Steel

Machine Speed : 20mtr/Min

Expanded Mesh Rib Lath Machine to Iran

Designed for production of plaster ribbing mesh

Light type rib lath machine for production of construction background plaster rib lath strips and coils.

The rib lath is a kind of light expanded mesh with diamond holes commonly.

The machine is supplied with feeding trolley, un-coiler, expanded main machine, roll profiling machine, hydraulic rib lath shearing machine, control cabinet and tooling.

|

|

|

|

| Main Parameter of Expanded Metal Press | |||||||

| TYPE | 25-6.3 | 25-16 | 25-25 | 25 - 63A | 25 - 63B | 25 - 160A | 25 - 160B |

| DEPTH | =1.0 mm | =1.0 mm | =1.5 mm | =2.5 mm | =3 mm | =6 mm | =6 mm |

| WIDTH | 500 mm | 1000 mm | 1250 mm | 2000 mm | 2000 mm | 2500 mm | 2500 mm |

| TIMES | 180/min | 150/ min | 150/ min | 70/ min | 45/ min | 70/ min | 20/ min |

| DISTANCE | 0-1.15 mm | 0-1.2 mm | 0-1.2 mm | 0-4 mm | 0-4 mm | 0-7 mm | 0-7 mm |

| LENGTH OF MESH | =20 mm | =25 mm | =30 mm | =100 mm | =200 mm | =250 mm | =250 mm |

| MOTOR | 2.2 KW | 3 KW | 4 KW | 11 KW | 11 KW | 22 KW | 22 KW |

| WEIGHT | 0.95 T | 2T | 3T | 10T | 10T | 18T | 20T |

| MEASUREMEENT | 950 *570 *1780 | 1800 *1320 *1550 | 1940 *1600 *2010 | 2400 *3500 *2300 | 2400 *3500 *2300 | 5500 *1750 *3300 | 5500 *1750 *3300 |

PuRuiSe machine can be used to produce Expanded Metal for following uses:

Air and Fluid Filters

EMI/RFI Shielding

Battery Cells

Ventilation Systems

Strainers

Partitions

Outdoor Furniture

Speaker Grills

Security Walls, Ceilings, Floors and Doors

Machine and Window Guards

Fencing

Shelving and Racks

Walkways and Stair Treads

Greenhouse Benches

No.33, Lingyuan Street, Anping, China Url:https://www.expanded-metal.org